Access the serpentine belt routing diagram and follow these essential steps for the 2005 Nissan Altima 2.5L (QR25DE engine):

Required Tools

- 15mm wrench or socket with ratchet

- New serpentine belt (e.g., Part Number 6PK2035)

- Mechanic's gloves (recommended)

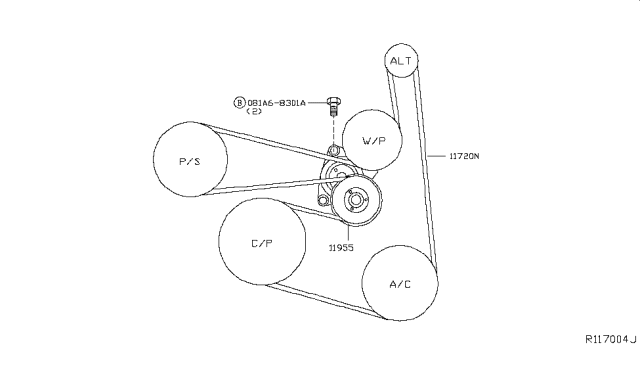

Serpentine Belt Routing Diagram

The belt follows this path around the pulleys:

Crankshaft (Bottom) → A/C Compressor → Idler Pulley → Power Steering Pump → Alternator → Coolant Pump → Tensioner Pulley

Key: The smooth side of the belt contacts the tensioner and coolant pump pulleys.

Quick Replacement Steps

1. Prepare Vehicle: Park on level ground, engage parking brake, turn engine off, and disconnect the negative battery terminal.

2. Locate Components: Identify all pulleys and the spring-loaded tensioner assembly (typically on driver's side).

3. Release Belt Tension: Insert the 15mm wrench onto the tensioner pulley bolt. Rotate the tensioner clockwise firmly against spring pressure to create slack.

4. Remove Old Belt: Slip the belt off one pulley (usually the alternator) while maintaining tensioner pressure. Carefully guide the entire belt off remaining pulleys.

5. Verify Correct Routing: Double-check the belt diagram above before installing the new belt.

6. Install New Belt: Route the new belt onto all pulleys except the tensioner, ensuring it sits correctly in all grooves. Route it over the tensioner pulley last.

7. Apply Tension: Rotate the tensioner clockwise again to create maximum slack. Slide the belt fully onto the tensioner pulley. Slowly release tensioner pressure.

8. Final Check: Ensure the belt is fully seated in all pulley grooves and properly aligned. Visually confirm routing matches diagram.

9. Reconnect Battery: Reattach the negative battery cable.

10. Test Operation: Start the engine and observe belt operation for 1-2 minutes. Listen for squealing or chirping indicating incorrect tension or routing.

Critical Warnings

Do NOT pry the tensioner body: Apply force only to the central tensioner pulley bolt. Forcing against the tensioner arm can cause failure.

Verify belt seating: Improper routing causes immediate damage. Triple-check the path against the diagram.

Worn tensioners or misaligned pulleys prevent proper tension. Replace faulty components immediately.