The head bolt torque specifications for the 2007 5.3L engine are not inherently wrong; they must be adhered to strictly as per GM factory service manuals to prevent catastrophic failures like head gasket leaks or warped heads. Deviating from these specs often stems from installation errors.

Common Mistakes and How to Avoid Them

Mistake 1: Skipping the Torque Sequence

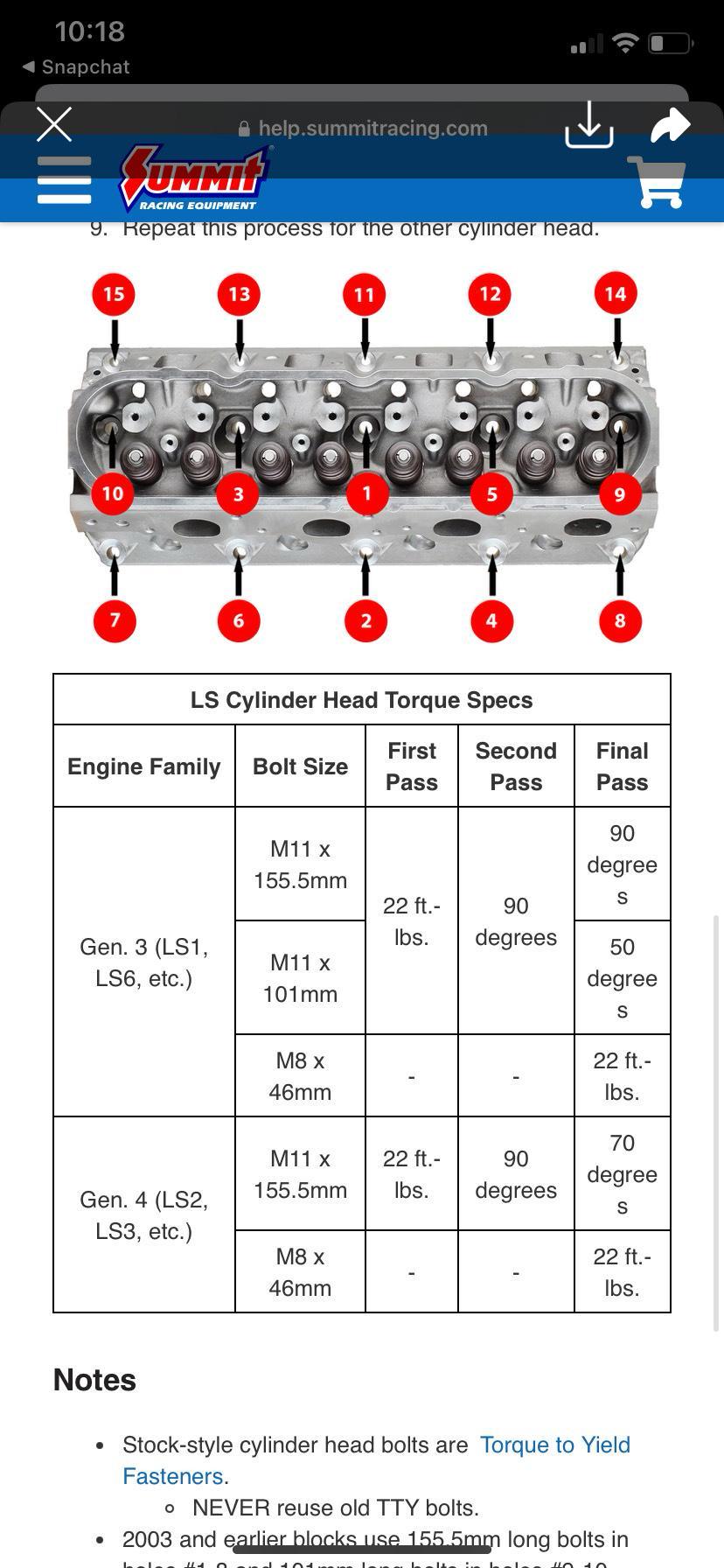

Applying bolts in the wrong order can unevenly stress the cylinder head. Always follow the manufacturer-prescribed sequence diagram, tightening incrementally (e.g., in multiple steps).

Mistake 2: Using Incorrect Torque Values

Inputting the wrong specification (e.g., confusing ft-lbs with Nm or mistaking bolt stages) leads to damage. Double-check values with a reliable service manual; for 2007 5.3L, initial torque is typically 44 ft-lbs, followed by angular rotations.

Mistake 3: Neglecting Bolt Lubrication

Dry bolts alter friction and torque accuracy, resulting in under/over-tightening. Apply light engine oil or specified thread lubricant as per guidelines to ensure consistent clamping force.

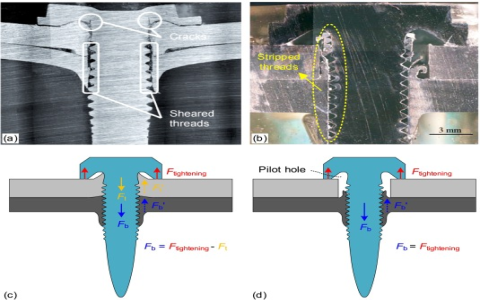

Mistake 4: Over-Tightening Bolts

Exceeding specs risks stretching or snapping TTY (torque-to-yield) bolts. Use a calibrated torque wrench and stop immediately at each stage, avoiding force.

Best Practices for Correct Installation

- Verify specs in certified documents: Cross-reference with official GM literature, not third-party sources.

- Use quality tools: A precision torque wrench ensures accuracy and prevents errors.

- Perform post-installation checks: After torquing, inspect for uniform seating and retest if leaks develop.