Electrical sensor failures on the 4L60E transmission manifest as erratic shifting, torque converter clutch (TCC) issues, limp mode (often fixed 3rd gear), and diagnostic trouble codes (DTCs). Targeting specific components resolves most problems:

Input Speed Sensor (ISS)

Symptoms: Harsh shifts (especially 1-2), P0716/P0717 codes, potential no-movement.

- Problem: Internal failure, damaged wiring/harness connector, debris accumulation.

- Fix: Verify sensor resistance (typically 700-1000Ω). Check wiring for shorts/opens. Clean sensor tip magnet. Replace sensor if faulty or contaminated.

Output Speed Sensor (OSS/VSS)

Symptoms: Speedometer fluctuations/inaccuracy, TCC engagement problems, harsh shifts, P0717/P0722 codes.

- Problem: Sensor failure, damaged wiring/harness connector, excessive gap.

- Fix: Test resistance (similar range to ISS). Inspect wiring harness thoroughly. Ensure correct sensor seating. Replace sensor if resistance is out of spec.

Throttle Position Sensor (TPS) & Manifold Absolute Pressure (MAP)

Symptoms: Early/late shifts, harsh shifts, erratic TCC lockup.

- Problem: Engine sensor, not transmission. Failed TPS/MAP provides incorrect engine load data to TCM.

- Fix: Diagnose TPS and MAP sensors using scan tool data and voltmeter. Refer to engine-specific service data for testing/replacement procedures.

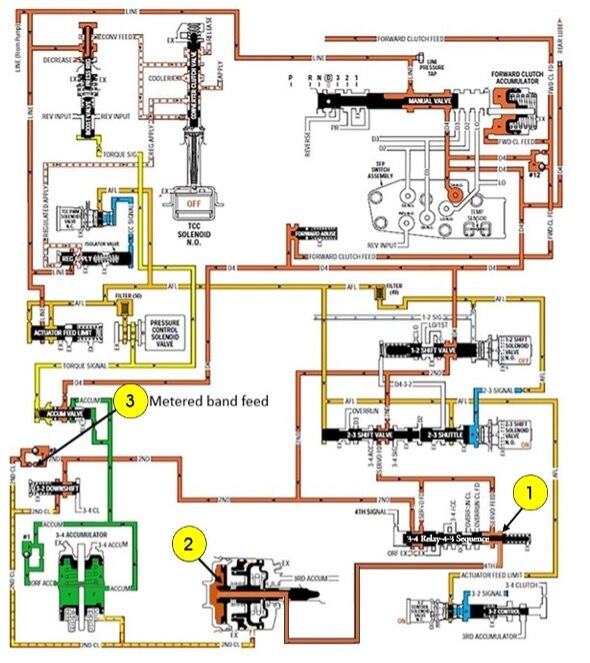

Shift Solenoid Valves (SS A, B, TCC)

Symptoms: Missing gears, stuck in one gear (limp mode), harsh TCC apply/release, P0751-P0758, P0740-P0742 codes.

- Problem: Internal solenoid coil failure, restricted solenoid fluid passages, harness issues.

- Fix: Measure solenoid resistance (18-30Ω typically at room temp). Check for excessive debris in valve body blocking screen/filter plate. Inspect solenoid harness connectors and wires. Replace faulty solenoids.

Harness and Connector Issues

Symptoms: Intermittent electrical problems, multiple seemingly unrelated DTCs.

- Problem: Corrosion at connectors (especially pan gasket/main case connector), damaged pins, chafed wires, poor grounds.

- Fix:

- Transmission Main Connector (Passenger Side): Inspect pins for damage/corrosion. Clean terminals meticulously. Ensure seal integrity. Check for internal harness damage.

- Internal Harness: Visually inspect entire harness route inside pan. Look for melted insulation, worn spots contacting case.

- Grounds: Locate main transmission case ground and engine grounds. Clean mounting points to bare metal and resecure tightly.

Key Diagnostic Practices

- Always retrieve DTCs first using a compatible scan tool.

- Use a Digital Multimeter (DMM) to test sensor resistance and circuit continuity/voltage where applicable.

- Inspect wiring harnesses thoroughly along their entire length for damage.

- Verify repairs: Clear DTCs and test drive through all gears and TCC operation to confirm resolution.