The 5.3 Vortec's plastic intake manifold is prone to specific failure points causing drivability issues. Key diagram areas and associated problems include:

1. Vacuum Leaks (Runner Flange & Port Seals)

Warping and deteriorated gaskets create leaks. Symptoms:

- Rough idle, especially when cold

- Check Engine Light (P0171/P0174 - System Lean)

- High idle or surging

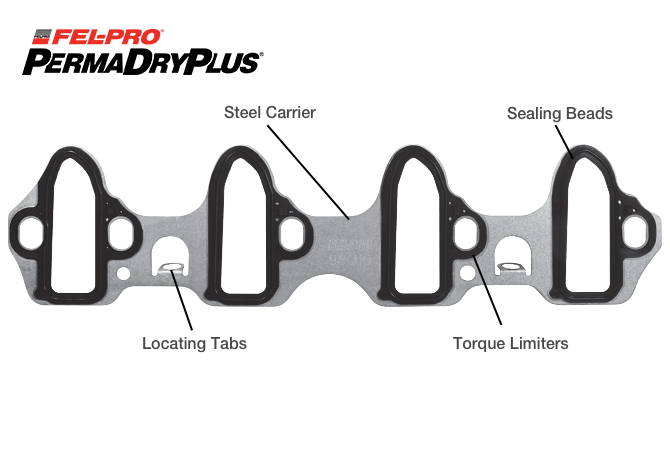

Solution: Inspect manifold flatness. Replace intake manifold gaskets and any cracked hard plastic vacuum lines. Ensure new gaskets are correctly seated.

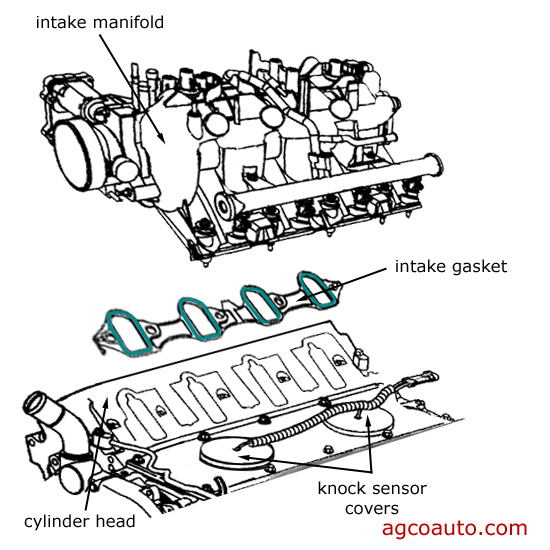

2. Coolant Leaks (Front/Rear Crossover Ports)

Worn or improperly seated gaskets at the manifold-to-head junctions leak coolant into lifter valleys or externally.

- Visible coolant at front/rear of engine

- Low coolant level

- Overheating potential

Solution: Replace manifold gaskets. Clean sealing surfaces meticulously. Use factory-spec torque sequence and values during reinstallation.

3. Cracked Plastic Manifold

Age and heat cycles cause fatigue cracks, often near mounting bosses or coolant ports.

- Vacuum leaks persisting after gasket replacement

- Coolant leaks originating from manifold body

Solution: Carefully inspect manifold, especially near the thermostat housing and heater hose ports. Replace the manifold if cracked.

4. MAP Sensor Port Clogging

The port inside the plenum can accumulate oil/carbon, skewing readings.

- Rough running, hesitation

- Check Engine Light (P0106, P0107, P0108)

Solution: Remove the MAP sensor and inspect/clean the small port in the manifold using appropriate cleaner and soft tools.

5. PCV System (Valley Cover & Breather Ports)

Clogged PCV orifice in the valley cover or manifold baffles causes excessive crankcase pressure and oil consumption.

- Oil consumption

- Oil in intake/throttle body

- May contribute to vacuum leaks

Solution: Clean manifold PCV baffles thoroughly during removal. Ensure updated valley cover with improved PCV orifice.

Troubleshooting Procedure

- Scan for stored diagnostic trouble codes (DTCs).

- Perform a thorough visual inspection for coolant leaks, oil seepage, or obvious cracks.

- Conduct a smoke test to pinpoint vacuum leaks, especially along the manifold sealing surfaces and ports.

- Check manifold surface flatness with a straightedge if leaks are suspected.

- Verify correct PCV system operation and cleanliness.