P1023 indicates a fault within the Throttle Actuator Control (TAC) Module's low voltage circuit (Bank 1). This requires immediate attention as it affects throttle response and engine performance.

Necessary Preparations

Gather these items:

- OBD-II scanner

- Digital Multimeter (DMM)

- Basic hand tools (screwdrivers, wrenches)

- Vehicle-specific service manual

- Electrical contact cleaner

- Dielectric grease

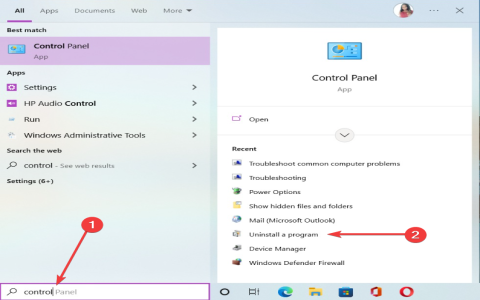

Step-by-Step Troubleshooting

1. Verify Code & Battery Voltage:

Re-scan with your OBD-II tool to confirm P1023. Check the vehicle battery voltage; it must read at least 12.6V when engine-off. Low battery voltage can cause erroneous faults.

2. Inspect Visual Connections:

Locate the TAC module (often near the throttle body) and the main Engine Control Module (ECM). Visually examine:

- Wiring harnesses for physical damage, chafing, or burns

- TAC module and ECM electrical connectors for corrosion, bent pins, or loose fit

- Ground points connected to the TAC system (cleanliness and tightness are critical)

Disconnect plugs and clean terminals using contact cleaner; apply dielectric grease upon reconnection.

3. Perform Voltage Checks with DMM:

Referencing the service manual wiring diagrams:

- Identify the TAC module's specific low-reference circuit.

- With ignition ON (engine OFF), measure voltage: Connect DMM ground probe securely to chassis ground. Backprobe the low-reference circuit wire at the TAC connector.

- A healthy circuit typically shows less than 0.5V. Voltages above 0.5V signify excessive resistance or a short.

- Similarly, check the power and ground circuits to the TAC module per specifications.

4. Continuity & Resistance Checks:

Power off and disconnect TAC/ECM! Use DMM resistance/continuity mode:

- Check continuity from the TAC low-reference pin to the designated ECM pin. No continuity confirms an open circuit.

- Measure resistance on the low-reference circuit between TAC and ECM. Resistance should be very low (< 5 Ohms). Higher resistance indicates corrosion or damaged wires.

- Verify ground circuit resistance to chassis (< 5 Ohms).

5. Check Related Sensors & Throttle Body:

Key inputs: Inspect the Throttle Position Sensor (TPS) and Accelerator Pedal Position (APP) sensor connectors/wiring. A faulty sensor can corrupt TAC communication. Manually check the throttle body for binding or excessive carbon buildup hindering movement.

Common Solutions

Based on findings:

- Repair Wiring: Fix damaged wires, corroded terminals, or loose ground connections found during testing.

- Replace Sensor(s): If APP or TPS shows faults or inconsistent readings, replacement is likely needed.

- Replace Throttle Body/TAC Module: If wiring/sensors are verified good but voltage/resistance faults persist, or mechanical throttle issues exist, replacement is necessary. Note: TAC/Throttle Body replacements often require a throttle relearn procedure (follow specific vehicle instructions).

- Replace ECM: Rare, but becomes probable if all low-reference circuit checks prove integrity and TAC module tests good.

Final Step: Clear all DTCs with your scanner. Perform a test drive under varied conditions to verify the P1023 code does not return.