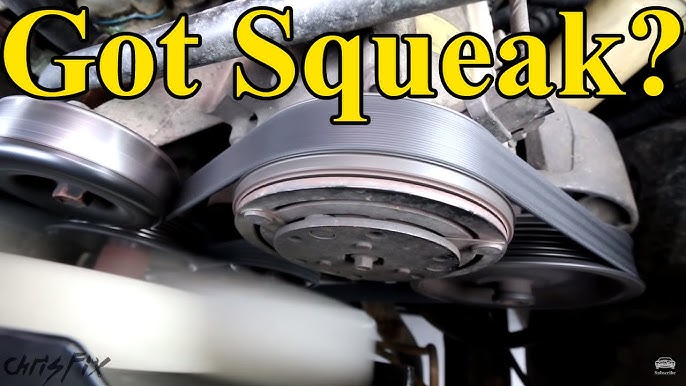

Squeaky belts on your 2008 Kia Spectra typically stem from insufficient tension, contamination, misalignment, or worn components. Correct belt routing, confirmed by the diagram, is the foundation for diagnosis.

Pre-Repair Safety & Preparation

Ensure the engine is cold and ignition is OFF. Disconnect the negative battery cable. Gather necessary tools: a flashlight, socket/wrench set (typically 12mm, 14mm, 17mm), breaker bar or suitable tensioning tool (check manual), belt dressing (optional, temporary fix), and gloves.

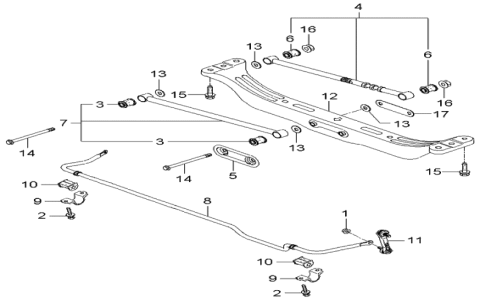

Locate and Verify the Belt Diagram

The belt diagram is essential for correct routing. Find the label under the hood, often on the radiator support, strut tower, or fan shroud. For the 2008 Spectra 2.0L engine:

- The serpentine belt wraps around the crankshaft pulley, alternator, power steering pump, A/C compressor, and idler/tensioner pulley(s).

- Verify the exact path depicted on your specific vehicle's diagram. Incorrect routing causes noise and damage.

Diagnosis Using the Diagram

- Inspect Belt Condition: Follow the routing path. Check for severe cracks (>3 per rib/inch), glazing (shiny spots), fraying, missing ribs, or oily contamination. Replace if worn.

- Check Belt Tension: Identify the automatic tensioner using the diagram. Press firmly on the tensioner arm with a wrench on the square drive. Belt deflection should be minimal (approx 1/4 inch midway on the longest span). Significant movement or ease of pressing indicates a weak tensioner needing replacement.

- Identify Pulleys: Use the diagram to locate the idler pulley(s) and tensioner pulley.

Resolving Squeaking

- Replace Worn Belt: Follow the diagram precisely during installation. Ensure the new belt matches old part number/grooves.

- Adjust/Replace Tensioner: If tension is low, apply force to the tensioner to increase belt tightness. If the tensioner is faulty (weak, seized, noisy bearing) or lacks adjustment range, replace it. Idler pulleys with noisy/rough bearings must also be replaced.

- Clean Contamination: Thoroughly degrease pulleys and replace the belt if contaminated with oil/coolant.

- Check Alignment: Visually inspect pulleys using a straight edge along the grooves; significant misalignment requires component replacement.

- Temporary Fix (Caution): Apply belt dressing sparingly only to the ribbed side of the belt while the engine is off. This is not a substitute for proper repair.

Verification

Reconnect the battery. Start the engine and listen carefully. The squeak should be eliminated. If it persists, recheck belt routing against the diagram, tension, and pulley bearings.