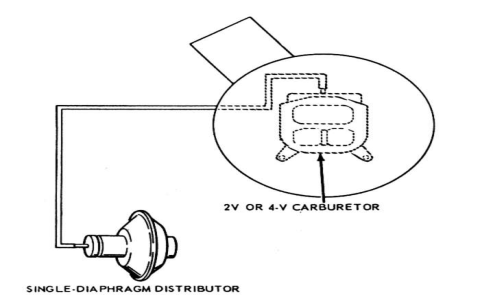

A carburetor vacuum line diagram visually details the connections of small diameter hoses linking the carburetor's vacuum ports to various engine components. Vacuum, generated by the piston intake strokes, is a critical control signal for engine management systems.

Understanding the Vacuum Lines

Carburetor vacuum ports supply manifold vacuum or timed (ported) vacuum signals depending on throttle plate position. Essential lines typically connect to:

- Vacuum Advance (Distributor): This crucial line connects to the distributor's vacuum advance diaphragm. Ported vacuum controls ignition timing advance, improving efficiency and throttle response.

- PCV Valve: The Positive Crankcase Ventilation (PCV) valve uses manifold vacuum to draw harmful blow-by gases out of the crankcase and into the intake for combustion.

- EGR Valve (Exhaust Gas Recirculation): Manifold vacuum activates the EGR valve under specific conditions, reducing combustion chamber temperatures and NOx emissions.

- Vapor Canister Purge: Manifold vacuum purges captured fuel vapors from the charcoal canister into the intake manifold.

- Modulator (Automatic Transmission): Certain transmissions use manifold vacuum via a modulator valve to control shift points based on engine load.

- Heater/AC Controls: Dashboard HVAC systems often utilize manifold vacuum to operate vent doors and mode controls.

- Vacuum Brake Booster: Although usually tapped directly from the intake manifold plenum behind the carburetor, it utilizes engine vacuum to assist braking.

Why Diagram Accuracy is Critical

- Misrouted Lines Cause Problems: Connecting to the wrong type of vacuum port (manifold vs. ported) significantly impacts performance, emissions, fuel economy, and drivability (hesitation, stalling, rough idle).

- Vacuum Leaks: Cracked, disconnected, or incorrectly sealed lines create vacuum leaks, leading to lean air/fuel mixtures, high idle, surging, and difficulty starting.

- Emissions Compliance: Correct routing ensures emissions control systems (EGR, PCV, Evap) function as designed.

- Ignition Timing: Correct vacuum advance signal is vital for proper ignition timing, power, and fuel efficiency.

Troubleshooting Key Symptoms

- High/Erratic Idle: Check for leaks at hose connections, cracked hoses, or lines disconnected from intake/vacuum source ports.

- Poor Performance/Hesitation: Verify vacuum advance line is connected to correct ported vacuum source and functioning. Check for leaks impairing signal to distributor diaphragm.

- Stalling: Inspect lines providing vacuum to critical components like the automatic transmission modulator or HVAC controls. Large leaks can destabilize idle.

- Failed Emissions Test: Ensure PCV, EGR, and Evap lines are correctly routed and leak-free.