Chevy 4.3L Head Bolt Torque Sequence & Procedure

Tightening cylinder head bolts correctly on your Chevy 4.3L engine is critical for proper sealing and preventing head gasket failure. Here's a concise guide:

Essential Preparation

- Ensure the engine block deck and cylinder head surfaces are clean and free of debris. Wipe clean with solvent and lint-free cloth. Clean all bolt holes thoroughly.

- Cylinder head bolts must be clean and lightly oiled only on the threads and under the bolt head using engine oil or the specific lubricant specified in the service manual (e.g., GM oil part # 12345501). Never use dry or thread-locked bolts unless specified.

- Verify bolt lengths if replacing bolts. Using incorrect bolts can cause damage.

- Ensure threads in the block are clean, undamaged, and chase if necessary (chase carefully, do not tap).

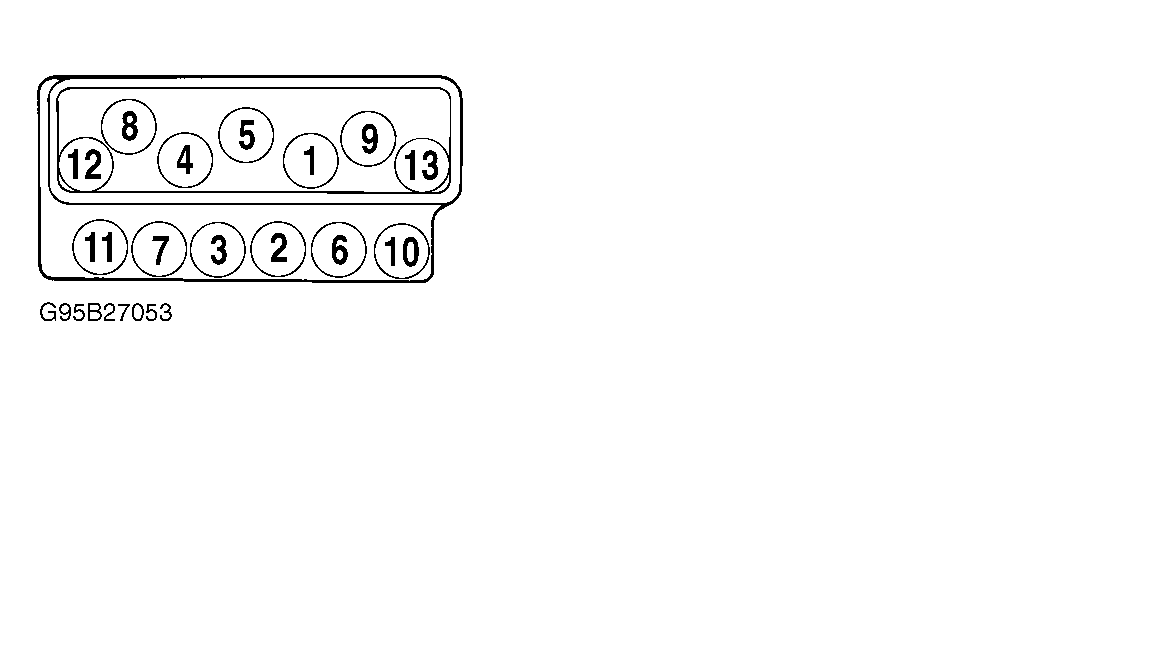

Torque Sequence

The firing order of the 4.3L V6 dictates a specific pattern to apply clamping force evenly. Sequences are often shown numerically or diagrammatically:

Numerical Sequence (Typical Pattern):

Driver Side (Left Bank):

- Front of Engine: 5 --- 3

- Center: 1 --- 2

- Rear: 6 --- 4

Passenger Side (Right Bank):

- Front of Engine: 11 --- 9

- Center: 7 --- 8

- Rear: 12 --- 10

Follow this path: Start at center bolt (1/7), move across head to opposite center (2/8), then outward following numerical order.

Torque Specifications & Procedure

Important: Values vary slightly between model years (pre-Vortec, Vortec) and specific head gasket instructions. ALWAYS CONSULT YOUR SERVICE MANUAL FIRST. Typical TTY (Torque-To-Yield) procedure:

- Stage 1: Torque all bolts to 22 ft-lbs (30 Nm) in sequence.

- Stage 2: Torque all bolts to 44 ft-lbs (60 Nm) in sequence.

- Stage 3: Tighten all bolts an additional 90 degrees (quarter turn) in sequence. This final stretch defines the TTY process. Use an angle gauge for accuracy.

Non-TTY Head Bolts (Less Common): If specified, follow stages (e.g., 30 ft-lbs, then 70 ft-lbs) but do not perform the angle tightening. Verify in manual.

Aluminum Heads (Special Note): GM often specifies a unique procedure for aluminum heads (common on later models). Typically: Torque all bolts to 37 ft-lbs (50 Nm) in sequence, then tighten all bolts an additional 130-140 degrees in sequence.

Critical Tips

- Always use a calibrated torque wrench for accuracy.

- Work on a cold engine (room temperature) unless the manual explicitly states otherwise.

- Torque bolts in multiple passes per stage, gradually increasing to the target value in the sequence order.

- After Stage 3, do NOT retorque the head bolts later. TTY bolts are designed for one-time stretch.

- Replacement head bolts are highly recommended, especially for TTY applications.