For immediate Dodge 360 V8 engine misfire troubleshooting, verify the firing order sequence and component integrity. Follow this structured approach:

Confirm Firing Order & Spark Plug Wiring

Use manual specifications only. The correct Dodge 360 (LA/Magnum) firing order is 1-8-4-3-6-5-7-2.

- Cylinder numbering:

- Driver's side (front to rear): 1, 3, 5, 7

- Passenger side (front to rear): 2, 4, 6, 8

- Visually trace every spark plug wire from the distributor cap (or coil packs) to the corresponding spark plug. Ensure connections are secure.

- Physically compare the current wire routing on your engine to a verified firing order diagram matching your year, distributor or coil-pack setup. A single misplaced wire causes misfires.

Inspect Ignition Components

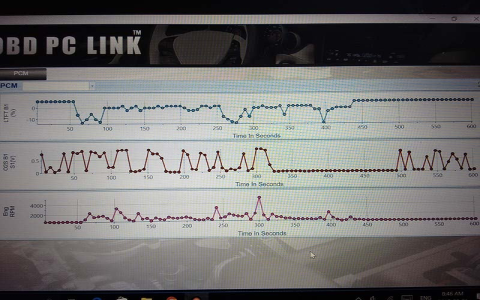

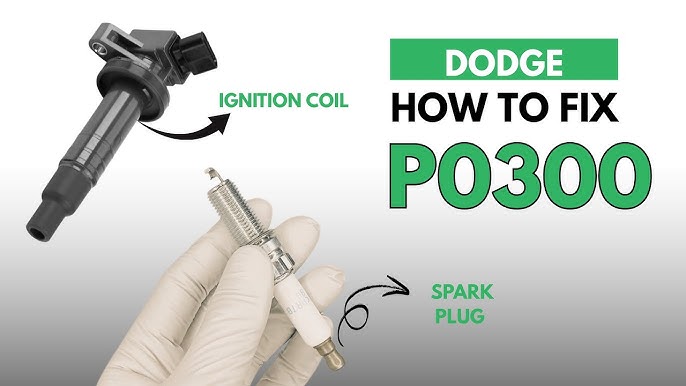

Focus on suspect cylinders if misfire codes (e.g., P030x) are present.

- Spark Plugs: Remove and inspect. Look for cracking, carbon tracking, excessive wear, or incorrect gap. Replace all if nearing service interval or showing damage.

- Ignition Coils: (Coil-on-Plug or DIS systems)

- Perform a swap test between the suspect coil and a known good coil (from a non-misfiring cylinder). Clear codes and run the engine. If the misfire code moves to the new cylinder, the coil is faulty.

- Inspect coils visually for cracks or carbon tracking.

- Distributor Cap & Rotor: (If equipped) Remove and inspect for moisture, carbon tracks, excessive wear, or corrosion on contacts/bushing. Replace at recommended intervals or if damaged.

- Spark Plug Wires: Check for physical damage (cuts, burns, abrasions), brittle insulation, or visible arcing (run engine in dark). Measure resistance; large deviations or open circuits indicate failure.

Check Wiring & Connections

- Inspect all ignition wiring harnesses, connectors at coils, injectors, and sensors for loose connections, bent pins, or corrosion. Disconnect, inspect, and firmly reconnect.

- Trace wiring paths for damage, chafing, or rodent chewing that could cause shorts or opens.

Address Other Critical Causes

If ignition checks pass, investigate other common misfire triggers:

- Fuel Delivery: Test fuel pressure at the rail (verify spec for your model). Check for clogged fuel injector(s) – listen for clicking with stethoscope or perform resistance/sweep test per service manual. Bad or stuck injectors prevent proper cylinder fueling.

- Compression: Perform a warm engine compression test on all cylinders. Low compression indicates internal mechanical issues (e.g., valves, piston rings).

- Vacuum Leaks: Significant vacuum leaks (especially large/unmetered air) near the intake manifold can cause global mixture issues leading to misfires. Check intake gaskets, PCV hoses, brake booster line.

Prioritize validating the firing order sequence first – it's the most common fixable cause. Methodically inspect plug wires, coils, and plugs, using swap tests where applicable to isolate faulty components efficiently. Diagnose engine codes systematically to target the affected cylinder(s).