A persistent belt squeak in your 2015 Nissan Altima 2.5L is commonly caused by a worn serpentine belt, failing tensioner, misaligned accessory, or contamination. Addressing it requires methodical troubleshooting and correct belt routing.

Essential Tools & Supplies

- New OE or Premium Serpentine Belt (e.g., Gates K060780)

- Serpentine Belt Tensioner Wrench (typically 14mm or 15mm square drive)

- Socket Set & Ratchet (10mm, 12mm, 14mm common)

- Torque Wrench

- Brake Cleaner & Lint-Free Rag

- Rubber Gloves & Safety Glasses

Understanding the Belt Routing

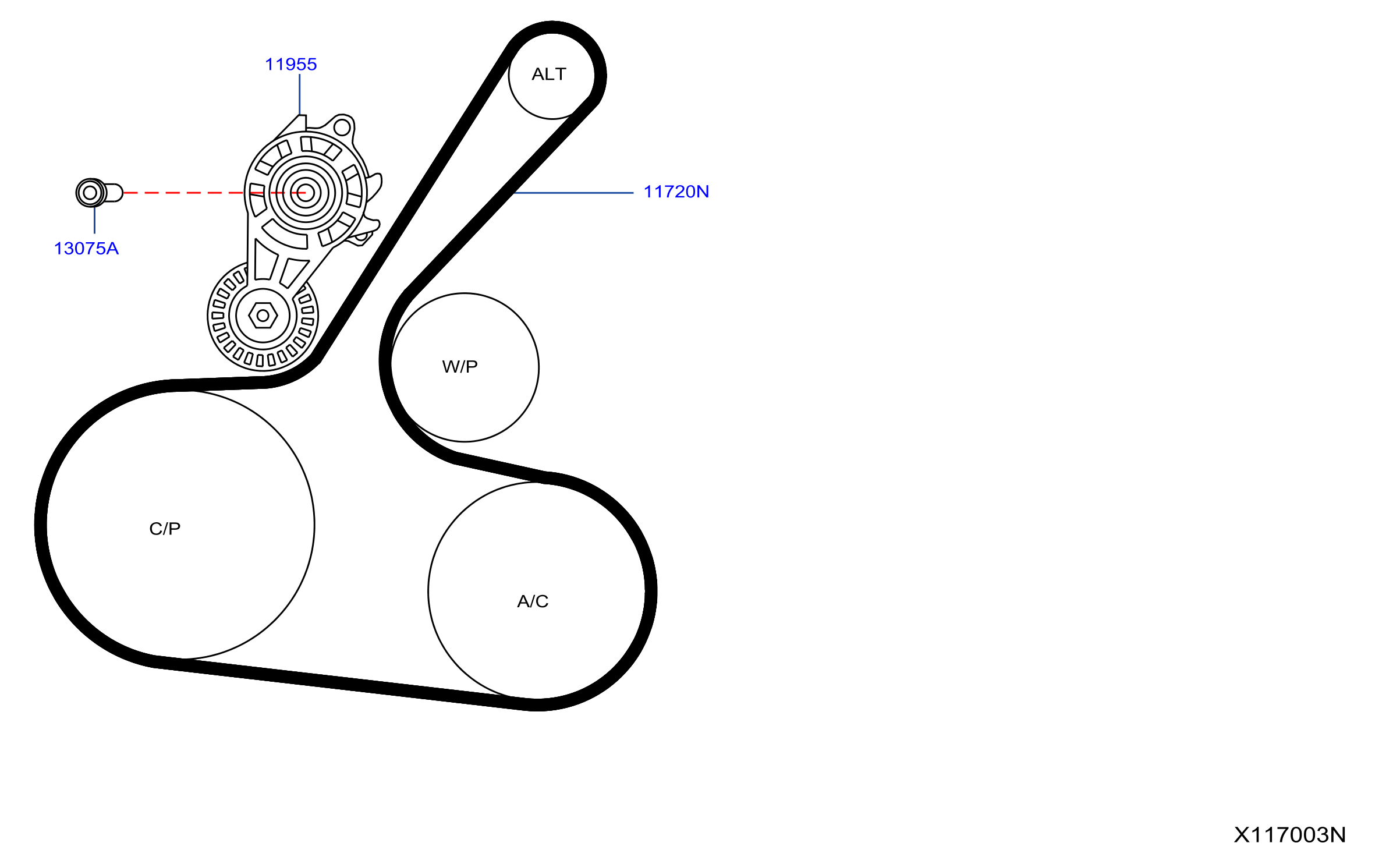

Referencing the 2015 Altima 2.5L diagram:

- The belt wraps clockwise around each component.

- It rides on the flat side of the tensioner pulley and idler pulley.

- It wraps around the outside of the crankshaft pulley (harmonic balancer).

- It wraps around the outside of the alternator pulley.

- It wraps around the outside of the power steering pump pulley.

- It wraps around the outside of the air conditioning compressor pulley.

Locate the Belt Tensioner: It's the spring-loaded arm with a pulley, usually positioned above the alternator on the QR25DE engine.

Troubleshooting & Replacement Procedure

1. Initial Diagnosis:

- Start the engine cold. Squeak on startup often indicates belt glazing or tensioner weakness.

- Mist a small amount of water on the belt ribs while running. If squeak stops temporarily, confirm belt wear or contamination. NEVER spray lubricants.

2. Visual Inspection:

- Check belt for cracks (especially deep ones in the ribs), fraying, glazing (shiny surface), missing ribs, or oil contamination.

- Inspect all pulleys for roughness while spinning by hand (engine off!), wobble, or seized bearings.

- Examine tensioner arm for smooth movement and signs of fluid leaks (if hydraulic).

- Check the harmonic balancer (crankshaft pulley) for any signs of separation or wobble when running.

3. Belt Removal:

- Disconnect the negative battery terminal for safety.

- Fit the tensioner wrench onto the tensioner’s square drive.

- Slowly rotate the tensioner clockwise to release belt tension (requires significant force).

- Slip the old belt off the easiest accessible pulley (usually the alternator or idler). Release the tensioner slowly.

4. Pulley Cleaning & Inspection (Critical Step):

- Thoroughly clean all pulley grooves using brake cleaner and lint-free rags. Remove all oil, grease, and debris. Ensure pulleys are DRY.

- Re-check pulley alignment and bearing condition (spin freely, no noise/play).

5. Installing the New Belt:

- Verify the new belt part number matches your Altima.

- Place the belt over every pulley EXCEPT the tensioner pulley or the easiest pulley to access last.

- Engage the diagram: Double-check routing follows the factory path meticulously before releasing tensioner.

- Fit the tensioner wrench and rotate clockwise until you can slip the belt onto the final pulley.

- Slowly release the tensioner until it's fully seated. The belt should feel snug.

- Visually re-confirm the belt is correctly seated in every pulley groove.

6. Post-Installation Checks:

- Reconnect the negative battery terminal.

- Start the engine and listen immediately for squeaks. A brief chirp (1-2 seconds) is normal as the belt seats. Persistent squealing indicates incorrect installation or another fault.

- Observe belt tracking – it should run true without walking off pulleys.

- Operate all accessories (A/C, power steering at full lock, high electrical load) to test tensioner operation under stress.

- Check tensioner deflection. Press firmly midway on the longest belt run. Normal deflection is roughly 1/4 inch. Excessive deflection points to a bad tensioner.

Key Considerations

Primary Cause: Belt misalignment or contamination causes most squeaks. Improper tensioning (usually insufficient) is next.

Avoid Overtightening: Rotating the tensioner further than necessary to slip the belt on damages bearings. Factory spring tension is correct.

Tensioner Failure: If the tensioner arm wobbles significantly, leaks, or fails to maintain tension, replace it immediately. A worn tensioner will quickly destroy the new belt.

Harmonic Balancer: Inspect carefully. Separation between the inner and outer sections causes severe belt misalignment and chirping/squealing.