Proper torque application on Ford 3.0L upper intake manifolds prevents vacuum leaks and coolant intrusion. Follow these specifications and error-correction protocols for reliable results.

Critical Torque Specifications

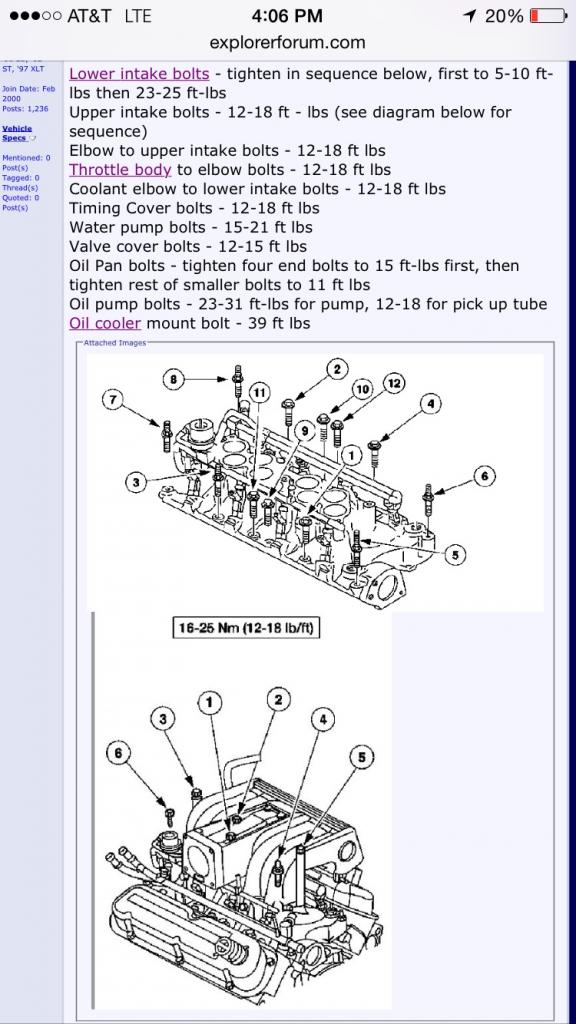

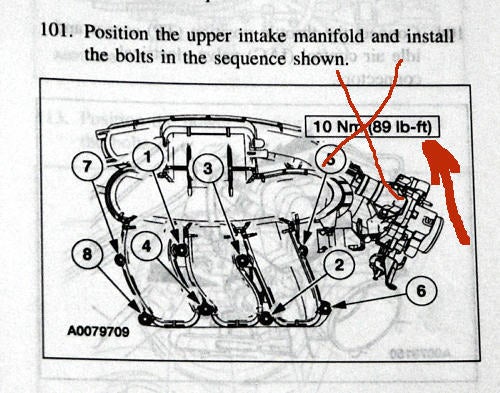

- Upper intake manifold bolts: Sequence in 3 progressive passes (6Nm → 10Nm → 12Nm / 53 in-lb → 89 in-lb → 106 in-lb)

- Throttle body mounting bolts: 10 Nm (89 in-lb)

- Fuel rail retaining bolts: 8 Nm (71 in-lb)

- PCV elbow fitting: Hand-tighten plus 1/4 turn

Top Installation Errors & Solutions

Error: Over-torquing center bolts

Fix: Replace stretched bolts immediately using calibrated torque wrench. Inspect manifold flange for warping.

Error: Incorrect throttle body gasket orientation

Fix: Verify gasket alignment arrows point toward throttle body shaft. Install new OEM gasket if deformed.

Error: Failed runner seal installation

Fix: Apply thin sealant (Ford TA-16 equivalent) to both sides of rubber seals. Ensure no sealant enters runner ports.

Verification Protocol

- Pressure test intake at 10 psi minimum after assembly

- Inspect for coolant weeping at manifold-cylinder head junction

- Monitor live data for MAP sensor fluctuation during test drive

Always retorque after first heat cycle (cool engine). Use factory service manual diagrams for bolt sequence patterns specific to your model year.