Toyota Tundra serpentine belts typically last between 60,000 to 100,000 miles. However, several factors can significantly influence this range:

Factors Affecting Serpentine Belt Lifespan

- Driving Conditions: Frequent short trips (prevents engine from fully warming, increasing condensation), stop-and-go traffic, dusty/sandy environments, and towing heavy loads accelerate wear.

- Climate: Extreme heat speeds up rubber degradation. Exposure to oil, coolant, or power steering fluid rapidly destroys the belt.

- Belt Quality: OEM or high-quality aftermarket belts usually last longer than cheap alternatives.

- Tensioner & Pulley Condition: A failing automatic tensioner or seized pulley/idler bearing creates excess stress or friction, shortening belt life.

Serpentine Belt Location & Routing (Typical V8 - Confirm Specific Engine)

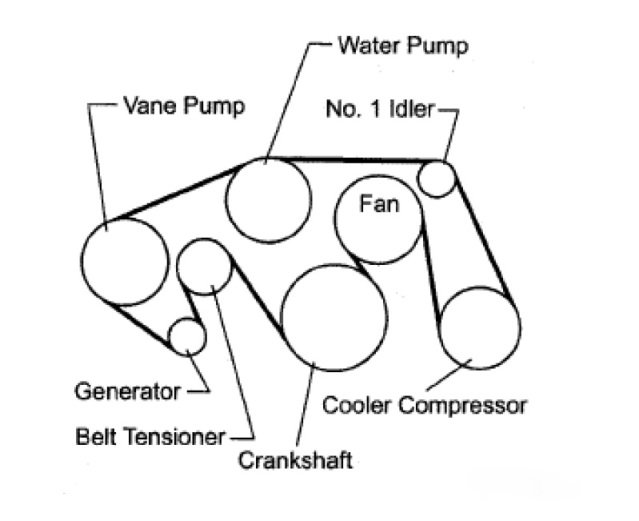

The serpentine belt is located on the front of the engine, driven by the crankshaft pulley. It loops around multiple accessories:

Typical Routing (Clockwise from Crankshaft):

- Crankshaft Pulley (Bottom center, largest pulley)

- Idler Pulley (Often top left/center)

- Alternator (Usually top right)

- Tensioner Pulley (Spring-loaded, position varies - key adjustment point)

- Air Conditioning Compressor (Often bottom left)

- Power Steering Pump (Often top center or right)

- Water Pump (Driven directly by the belt on most Tundras, crucial for cooling)

Critical: Consult the belt routing diagram sticker typically located on the radiator support or underside of the hood. Always draw or photograph the existing belt routing before removal.

Essential Inspection & Replacement Tips

- Regular Visual Checks (Every Oil Change): Look for cracks (especially on the ribbed side), fraying, glazing (shiny surface), missing chunks, or excessive rubber build-up in pulley grooves. Shine a flashlight along its length.

- Listen for Tells: Squealing (often on startup or during wet conditions - tension or glazing), chirping (misalignment or wear), or rumbling (bad idler/tensioner bearing).

- Check Tensioner Operation: With engine off, use a wrench on the tensioner arm (if possible per design) to see if it moves smoothly against the spring pressure and holds tension. Excessive wobble in any pulley indicates bearing failure.

- Replace Belt & Components Together: It's highly recommended to replace the automatic tensioner assembly and all idler pulleys when replacing the serpentine belt, especially near or over 100k miles. They are common failure points that can ruin a new belt quickly.

- Use Correct Tools: Use the correct size socket/wrench on the tensioner's square drive (usually 3/8" or 1/2") to relieve tension safely. Never use a pry bar directly on the belt or tensioner pulley bracket.

- Verify New Belt Routing: Triple-check the new belt routing against your diagram/sticker/photograph before releasing tension.

Never ignore a worn or noisy serpentine belt. Failure causes immediate loss of power steering, charging, and critically, the water pump stops circulating coolant, leading to severe engine overheating and damage within minutes.