Installing a headlight switch wiring harness in a Chevy truck requires basic mechanical skill and electrical knowledge. Always disconnect the negative battery terminal before starting any electrical work. Below is a concise guide, referencing a typical wiring diagram configuration.

Tools & Materials

- New OEM or compatible headlight switch

- Wire strippers/crimpers

- Electrical tape or heat shrink tubing

- Multimeter (recommended for verification)

- Basic hand tools (screwdrivers, panel removal tools)

- Repair connectors/wire (if splicing required)

Procedure

1. Disconnect Battery: Locate the negative (-) battery terminal and disconnect it completely to eliminate shock/fire risk and prevent accidental shorts.

2. Access the Switch:

- Parking Brake: Set firmly.

- Remove Dash Trim Panels: Carefully use appropriate tools to pry off trim bezels surrounding the instrument cluster and headlight switch. Specific panel locations vary by model year.

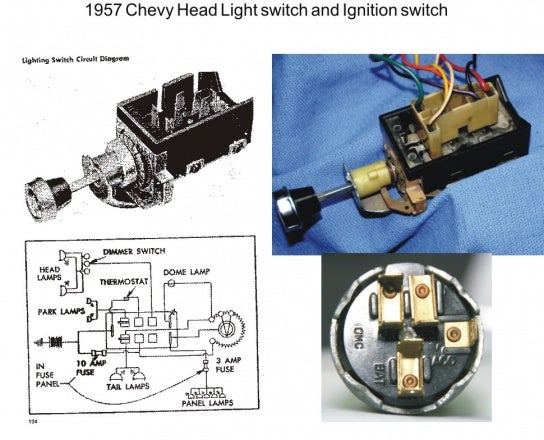

- Locate Switch: Identify the factory headlight switch assembly.

3. Remove Old Switch:

- Push Knob In & Depress Release Tab: Most Chevy switches require pushing the knob fully inward while simultaneously depressing a small tab (often on the top surface of the switch) to unlock it from the bezel.

- Pull Knob/Switch Assembly Out: Once the release tab is depressed, pull the entire knob and switch assembly outward from the dashboard.

- Unplug Wiring Harness: Locate the multi-pin connector at the rear of the switch and depress any locking tab. Carefully pull the connector straight off the switch terminals.

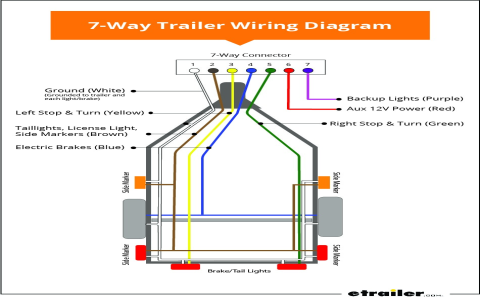

4. Identify Wires (Diagram Reference): Consult your specific year/model Chevy truck wiring diagram. Match wire colors/terminal markings on the harness connector to the diagram. Common functions include:

- Battery Power Supply: Typically Orange (constant 12V+, often fused).

- Headlight Power Output (Low Beam): Often Tan wire.

- Headlight Power Output (High Beam): Often Light Green.

- Parking Light Output: Often Brown or Dark Brown.

- Dimmer Rheostat (Dash Lights): Often Gray or similar (variable power).

- Instrument Illumination Feed: Often Gray/Yellow.

- Ground: Typically Black (essential).

- Dome Light/Delay Feed: Often Purple/Yellow (used for door-activated interior lights/delay).

Critical: Verify wire functions using your truck's diagram as color codes can differ.

5. Install New Switch:

- Plug in Connector: Ensure connector pins align correctly and push the harness connector firmly onto the terminals of the new headlight switch until it clicks/locks securely.

- Test Functions (Optional but Recommended): Temporarily reconnect the negative battery cable. Without installing the switch into the dash, turn the knob/dimmer to verify:

- Parking lights activate

- Headlights (Low & High beam) function

- Dome light delay works (if applicable)

- Dash illumination dims/brightens

Disconnect battery negative immediately after testing.

- Position Switch: Carefully position the new switch assembly into the dash opening.

- Lock Switch: Push the knob fully inward to engage the locking mechanism (usually the same release tab used for removal snaps back into place). The switch should be firmly seated.

6. Reassemble:

- Replace all trim panels and bezels securely.

- Reconnect Battery: Attach the negative battery terminal last.

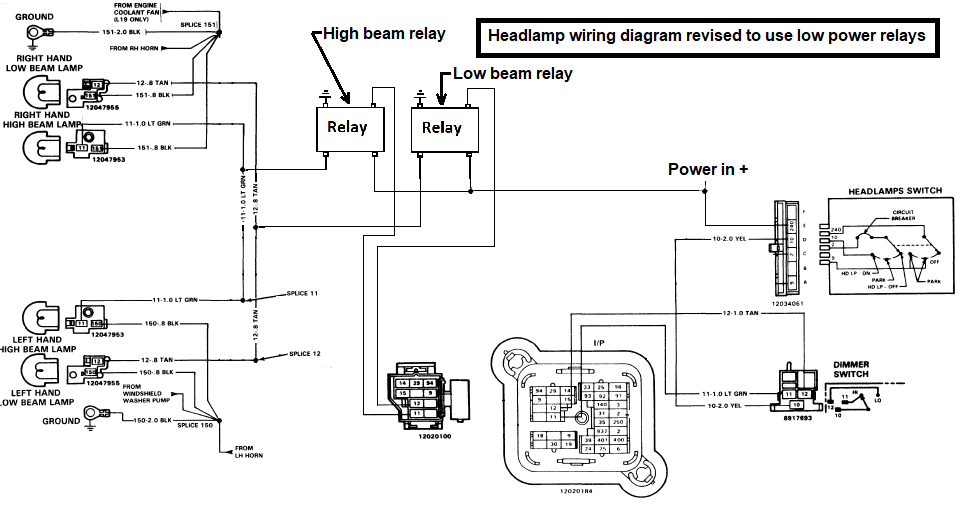

Basic Wiring Concept Diagram

Understanding the core connections aids troubleshooting:

- Power In: Constant 12V+ (e.g., Orange wire) feeds the switch.

- Power Out: Switch routes power to:

- Parking Lights (Brown)

- Low Beams (Tan)

- High Beams (Light Green - usually via separate relay control)

- Ground: Black wire to chassis ground completes all circuits.

- Dash Dimming: Gray wire provides variable power to illumination lights.

- Dome Feed: Purple/Yellow wire connects to interior light circuit.

Key Tips:

- Diagram is Essential: Never rely on memory; use the specific diagram for your truck.

- Secure Connections: Ensure terminals are clean and connectors seat fully. Loose connections cause flickering or failure.

- Protect Wiring: Avoid routing wires near sharp edges or moving parts; use existing grommets through the firewall.

- Replace Damaged Plugs: If the connector is brittle/broken, replace the pigtail.

If wiring is significantly damaged or modified, consult a professional.