Locating the serpentine belt diagram for your 2003 Honda CRV is straightforward. Focus on these primary locations and methods:

1. Check Under the Hood (Most Common Location)

Examine the engine compartment carefully:

- Radiator Support: Look for a decal or sticker on top of the radiator core support. This is the most frequent placement.

- Hood: Check the underside of the hood itself.

- Strut Tower: Inspect the front suspension strut tower covers or nearby flat surfaces.

- Fan Shroud: Examine the top or front face of the plastic fan shroud surrounding the radiator.

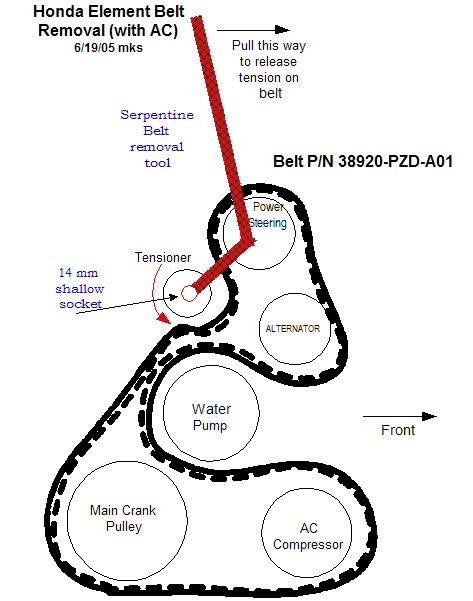

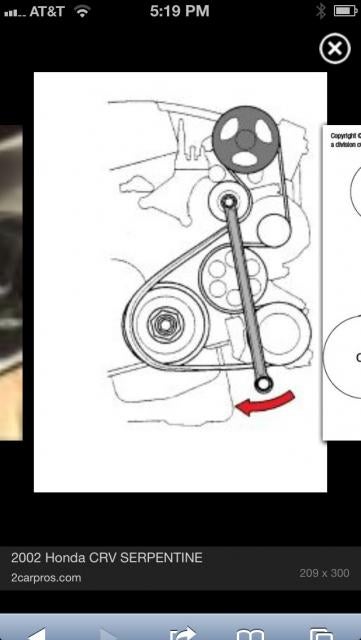

Look for a diagram clearly showing the belt's routing path around each pulley.

2. Consult Your Owner's Manual

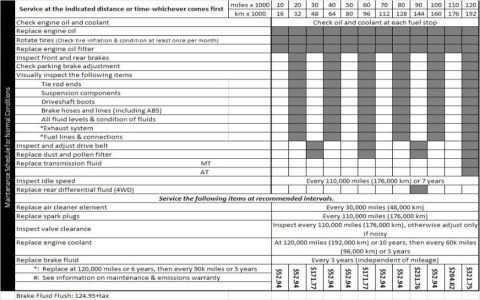

While less common for detailed engine diagrams, some Honda owner's manuals contain this information or point to the engine bay location.

3. Use Your Factory Service Manual (Most Authoritative)

If you have access to the official Honda Service Manual for the 2003 CRV:

- Refer to the Engine Mechanical section.

- Look specifically for Serpentine Belt Replacement, Drive Belt, or Accessory Belt Routing. A diagram will be included.

4. Contact a Honda Dealership Parts Department

Provide them with your Vehicle Identification Number (VIN). They can often:

- Locate the correct belt routing diagram specific to your engine.

- Confirm or describe the routing path.

5. Reference a Reputable Aftermarket Repair Manual

Manuals like those from Chilton or Haynes contain belt routing diagrams specific to the 2003 CRV.

Key Considerations

- Engine Type: The 2003 CRV primarily used the K24A1 engine (2.4L i-VTEC). Belt routing was generally consistent for this model year.

- Optional Equipment: Ensure the diagram matches your specific configuration, especially if you have a vehicle without factory air conditioning (unlikely but possible).

- Component Position: Idler pulleys and tensioners can differ slightly in placement depending on the exact VIN. The diagram shows the precise path.

- Label Condition: Under-hood labels can fade or become damaged over time. If missing, use another method.

Always verify the belt routing against your actual engine before final tensioning. Correct routing is critical for accessory function and belt lifespan.