Creating a motorcycle mirror wiring diagram requires understanding your bike’s electrical system and planning connections clearly. Follow these steps for a functional DIY setup.

Required Tools and Materials

- Multimeter for voltage testing

- Wire strippers and crimping tool

- Heat-shrink tubing or electrical tape

- Soldering iron and solder (optional for secure connections)

- Circuit tester or test light

- Zipties and wire loom for organization

Step-by-Step Diagram Creation

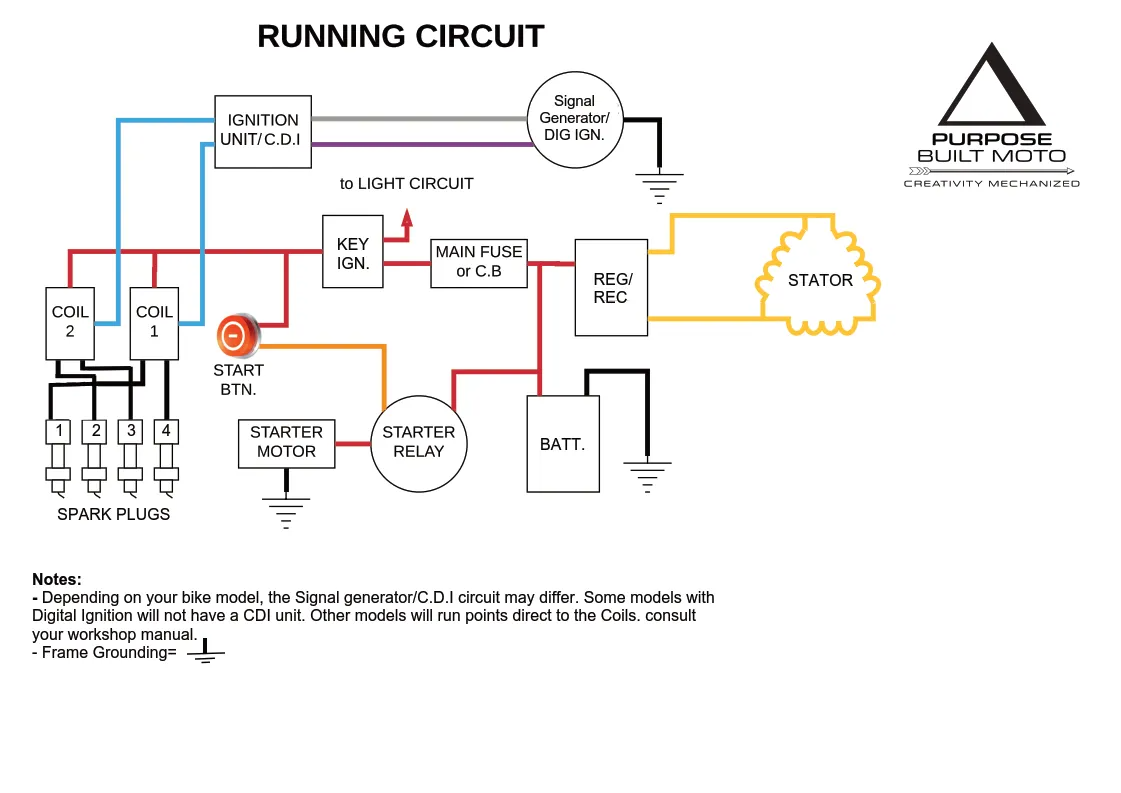

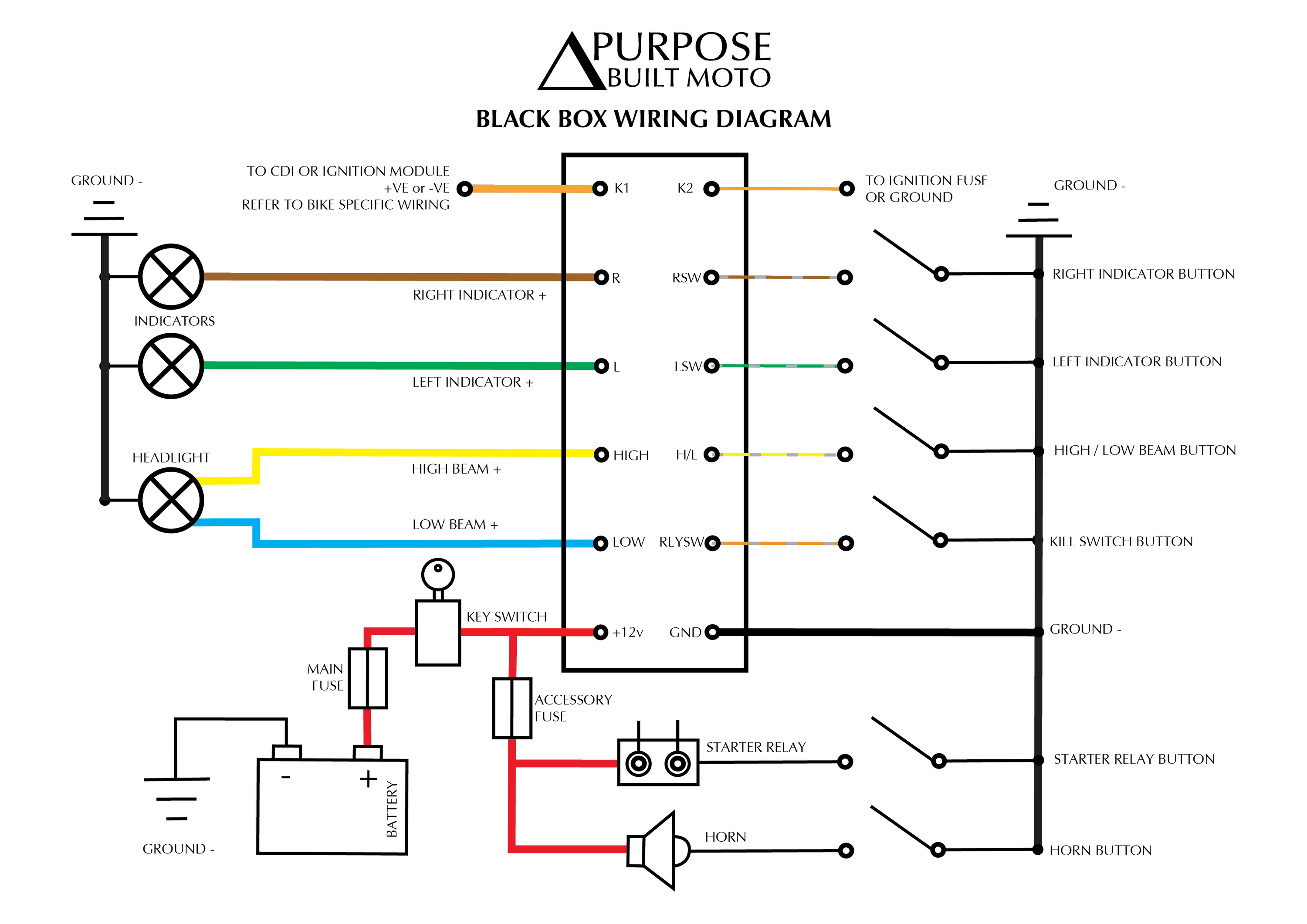

1. Identify Power Sources: Locate switched ignition power (activates with key) and ground points using a multimeter. Common sources include accessory fuse taps or spare connectors near the handlebars. Avoid direct battery connections to prevent drain.

2. Map Mirror Functions: Determine if mirrors have turn signals, heating, or adjustment motors. Note wire colors and functions using manufacturer documentation or continuity testing.

3. Sketch the Circuit: Draw a schematic with:

- Power source (labeled with voltage, e.g., 12V)

- Fuse (3-5A recommended)

- Switch or relay for heated mirrors (if applicable)

- Ground symbol for all ground connections

- Wire paths between components

Use standard symbols and label wire colors.

4. Calculate Wire Gauge: Use 18-22 AWG wire for low-current mirrors. For heated mirrors or high-power LEDs, choose 14-16 AWG to handle load. Cross-reference ampacity charts.

5. Plan Routing: Trace paths from mirrors to power/ground avoiding moving parts, heat sources, and sharp edges. Designate a common grounding point near the frame.

Safety and Installation Tips

- Disconnect the battery before wiring.

- Solder and seal connections with heat-shrink tubing for waterproofing.

- Test circuits with a multimeter before permanent mounting.

- Secure wires every 6 inches with zipties to prevent vibration damage.

Troubleshooting

No Power: Verify fuse integrity and ground continuity. Check for corroded terminals.

Intermittent Operation: Inspect for pinched wires or loose connectors. Reflow solder joints if needed.

Signal Malfunction: Ensure turn signal wires don’t share circuits with incompatible components.