Mastering GMT400 firewall connector diagnostics requires understanding their dual-connector system, typically C100 (smaller, often near brake booster) and C200 (larger, center). Here’s the pro approach:

Essential Preparation

Tools Required:

- Factory Service Manual electrical section for your specific year and model

- Digital Multimeter (DMM)

- Test light

- Terminal depinning tool kit

- Quality terminal probe kit

- Safety glasses

Critical First Step:

- Disconnect the negative battery terminal before probing connectors to prevent short circuits.

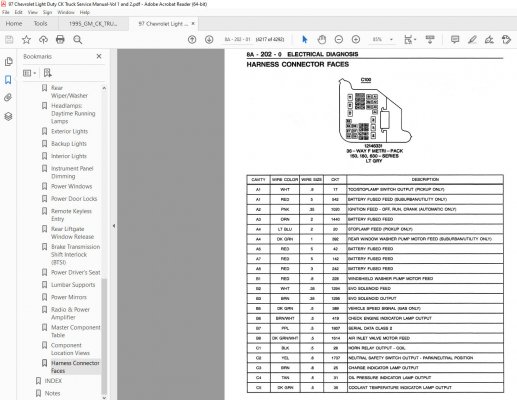

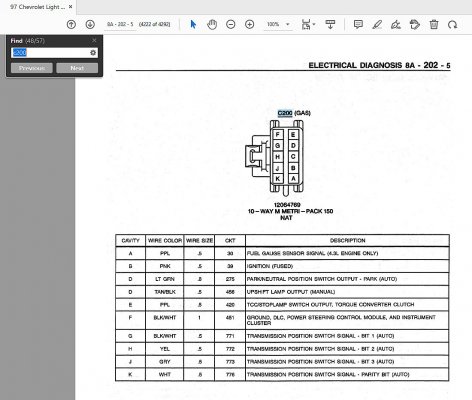

Pinout Identification Process

1. Connector Physical Identification & Orientation:

- Identify C100 and C100 locations reliably using manual diagrams, not assumptions.

- Note connector halves: Front (engine bay side) mates with Rear (cab side). Pin numbering is relative to each half.

2. Pin Numbering Decoding:

- Locate tiny molded numbers/letters or arrows indicating Pin 1 position on connector housing.

- Rows usually marked alphabetically top-to-bottom (e.g., row A, B, C).

- Columns marked numerically left-to-right from Pin 1.

- Pro Tip: If markings are damaged, always reference the mating connector's pinout and trace continuity.

3. Service Manual Pinout Interpretation:

- The manual lists each circuit by Pin Number (e.g., C100-Front, Pin C7), Wire Color, Circuit Function (e.g., "IGN 1 Feed to ECM").

- Verify Wire Color: Faded or repainted wires require probing confirmation.

- Circuit Functions Vary: Never assume; check exact model/year. PCM/ECM inputs, grounds, fused feeds share connectors.

4. Pro Probing Techniques:

- Backprobing: Insert probe tip gently into connector rear through the weather seal using terminal-specific probes.

- Disconnect & Probing: Remove connector halves, probe terminals using the proper pin guide.

- Test Logic:

- For Grounds: Confirm continuity between pin and chassis ground.

- For Powers/Feeds: Verify voltage present under load with test light/DMM after reconnecting battery/connectors.

5. Troubleshooting Specifics:

- Bad Grounds: Check multiple grounds simultaneously. Suspect corroded pins if voltage drops under load. Voltage reference checks are critical for sensors.

- Open Circuits: Probe pin-to-pin continuity through the firewall between connector halves.

- Short Circuits: Perform isolation resistance tests to power and ground.

Pro Technician Tips:

- Corrosion First: Most issues stem from corroded terminals. Remove pins, clean contacts with electrical cleaner.

- Inspect Terminal Tension: Use terminal test pins to ensure secure mating. Replace loose terminals using proper GM-Spec pins and tools.

- Year Matters: OBD-I (94-95) and OBD-II (96+) have significant ECM/PCM pinout differences.

- Manual Supplement: Cross-reference ground splice pack locations noted in the manual for thorough diagnosis.