Diagnosing serpentine belt issues in a 2000 Toyota Corolla (typically equipped with the 1.8L 1ZZ-FE engine) often involves incorrect routing, improper tension, or failing components. Follow this guide:

Confirming Correct Belt Routing

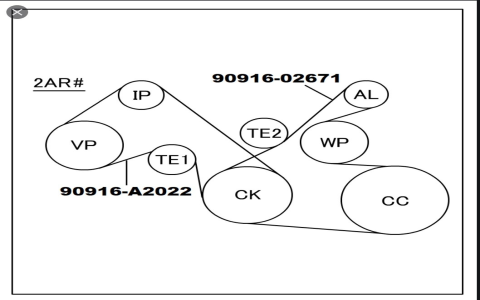

The factory routing path is critical. For the most common configuration (single accessory belt driving alternator, power steering pump, water pump, and A/C compressor):

- Crankshaft Pulley: The belt wraps around the bottom of the crankshaft pulley groove.

- Water Pump Pulley: The belt wraps around the right-hand side (passenger side) of the water pump pulley. This is a key directional point often missed.

- Idler Pulley: The belt wraps around the outer (smooth) side of the automatic tensioner idler pulley.

- A/C Compressor Pulley: The belt wraps around the outer/top groove of the A/C compressor pulley.

- Power Steering Pump Pulley: The belt wraps around the front groove of the power steering pump pulley (closest to radiator).

- Alternator Pulley: The belt wraps around the lower front groove of the alternator pulley.

- Automatic Tensioner Pulley: The belt wraps around the inner ribbed side of the automatic tensioner pulley itself.

Simplified Path (Imagine): Crankshaft (Bottom) -> Water Pump (Right Side) -> Idler Pulley (Smooth Outer Side) -> A/C Compressor (Outer Groove) -> Power Steering Pump (Front Groove) -> Alternator (Lower Groove) -> Automatic Tensioner Pulley (Ribbed Inner Side). This creates an "S" shape similar to many Honda CR-V diagrams.

Common Symptoms & Solutions

- Squealing/Squeaking (Especially on Startup/Cold/Damp):

- Primary Cause: Low Tension - Automatic tensioner spring weak/damaged/stuck. Inspect tensioner movement. Replace if weak or binding.

- Other Causes: Belt glazing/contamination (oil/coolant), misalignment, worn idler pulley bearing.

- Squealing During Specific Actions (e.g., Turning Steering Wheel):

- Primary Cause: Power Steering Load - Check power steering fluid level first. Belt slip under load indicates marginal tension or failing PS pump. Recheck tensioner.

- Rattling/Chirping (Constant or Intermittent):

- Primary Cause: Failing Idler/Tensioner Pulley Bearings - Spin each pulley manually (engine off!) with belt removed. Grinding, roughness, or significant wobble means replace that pulley. Listen with mechanic's stethoscope while running.

- Belt Shredding/Edge Wear/Throwing the Belt:

- Primary Causes:

- Misrouted Belt: Double-check routing against factory diagram (Water Pump direction is critical!).

- Severe Pulley Misalignment: Check all accessory pulleys (A/C, PS, Alt) are not bent or damaged.

- Failed Bearing (Idler/Tensioner/Alternator/Etc.): Causes pulley wobble, shredding belt edges. Inspect all pulleys closely.

- Primary Causes:

- Visible Cracks/Glazing on Belt Ribs:

- Primary Cause: Old/Aged Belt - Replace immediately, inspect underlying cause for accelerated wear (tension, contamination).

- Battery Light On/Overheating:

- Primary Cause: Loss of Drive - Belt broken or slipped off completely. Alternator not charging (battery light) or water pump not circulating coolant (overheating). Replace belt immediately after diagnosing cause of failure.

Critical Installation Steps

- Verify Tensioner Function: Before installing new belt, move the tensioner arm clockwise (against spring pressure) using a wrench/socket. It should move smoothly and return forcefully. Any stiffness, binding, or weak return mandates replacing the entire tensioner assembly.

- Inspect All Pulleys: Ensure pulleys spin freely and smoothly without grinding or wobble. Replace any defective pulleys (idler, tensioner pulley, accessory).

- Check Pulley Grooves: Clean out debris. Severe rust or grooves packed with old belt material can cause premature failure.

- Align New Belt Correctly: Triple-check the routing against a verified diagram before releasing the tensioner. Ensure belt is fully seated in all grooves.

- Torque Specs: If removing the tensioner/idler bracket (common for water pump access), refer to repair manual for correct tightening sequence and torque values on reinstallation to prevent misalignment.

Always disconnect the negative battery cable before starting work. Proper routing, a healthy tensioner/idler, and ensuring pulleys are true are paramount for reliable operation.